Need advice? You can reach us at + 31 (0)161 45 30 98

Need advice? You can reach us at

+ 31 (0)161 45 30 98

Activated Alumina

High quality activated alumina for every drying application

Water removal steps appear everywhere in industry with activated alumina standing in the forefront of the several different materials available. The low cost of alumina, its chemical and physical resistance, its regenerability and its high capacity for retaining water are among the reasons for its widespread acceptance.

AxSorb® D spheres. This product has been specifically developed for air drying. A smooth aspect of the grain has been designed for improved mechanical properties. Very high attrition resistance and crush strength are combined with high surface area and static adsorption capacity to give AxSorb® D the features required for the most demanding and safest drying operating conditions.

We offer consistently high quality aluminas that feature high mechanical strength, adsorptive properties and resistance to aging. At D&F Techniek you get the insurance that every single batch is tested on adsorption capacity.

Mechanical Strength

Our activated alumina has a very high resistance to attrition and crushing. This is a result of the production process and the spherical form of the grains. The attrition and crushing values for spheres are well adapted to their applications, the spherical form making possible homogeneous and compact loading with very little subsequent settling. Higher flow rates are allowed and taller drying vessels can be used

Adsorption Characteristics

Adsorption is a process in which a gas or vapor adheres to the surface of a solid without intimate admixture with the atoms of the solid: this is the case with activated alumina. Since adsorption is a surface phenomenon, good adsorbents are those which present large surface areas per unit mass and which have high attractive forces for the target species. The adsorption capacity is directly proportional to the surface exposed and the pressure or concentration of the material to be adsorbed. The optimized high porosity of activated alumina gives a high specific surface and a large adsorption capacity per unit weight. Even when saturated with water, activated alumina looks and feels dry. Also, activated alumina is chemically inert toward most liquids and gases. Its excellent resistance to fouling by olefins is the reason for its wide use in the treatment of petrochemicals.

Aging

Aging In a commercial unit, hydrothermal deterioration and chemical contamination or fouling are the two main causes of alumina aging.

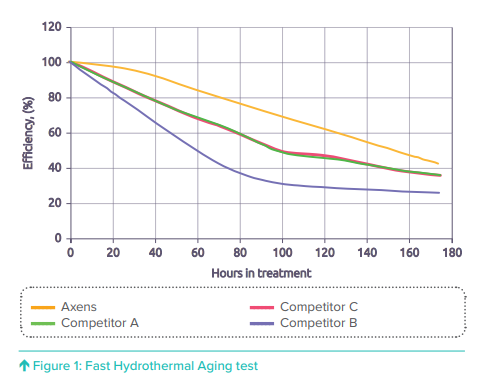

- Hydrothermal aging Hydrothermal aging is the result of a gradual irreversible change of the alumina structure, generally due to hydrothermal treatment during regeneration. Aging is mainly dependent on the number of regenerations (i.e., adsorption/desorption cycles). This is why it pays to regenerate at longer intervals by using the available capacity to its fullest extent. This is done by adjusting the cycle length. The main consequence is the surface area reduction due to a “collapsed pores” effect. Under normal working conditions, aging brings about a 50% decrease in the initial properties of the alumina in a period of two to four years. Accelerated hydrothermal tests by an independent organization show that AxSorb® D grade, for example, stands significantly above the competition (see Figure 1)

- Aging by Contamination or Fouling Theoretically reversible, this form of aging occurs when the active surface of the alumina is coated or access to its active sites is blocked by either a direct deposit of oil, or by degradation, polymerization or oxidation of unstable compounds present in the fluid passing through the alumina. In practice, the phenomenon is not completely reversible and immobile carbon deposits increase at each regeneration, leading to a progressive decrease of the adsorption dynamic capacity. Aluminas manufactured by Axens have earned wide recognition in comparison with standard market solutions. The high surface area and tailored pore distribution provide a high dynamic water adsorption capacity, coupled with excellent physical and mechanical properties. Their outstanding stability yields a long life time by achieving low water dew point, both with TSA (Temperature Swing Adsorption) and PSA (Pressure Swing Adsorption) processes.

Need assistance? You can reach our sales team at +31 161 45 30 98 or send us an E-mail.